Intaglio Printing

The Vintage Look

His light etchings are a symbiosis of classic etching and photography. Each print on the copperplate paper is unique. The application of the copperplate oil colour, the rubbing of the etching plate with gauze and the printing on the etching press are carried out by hand for each print, just as with copperplate engraving.

Ralph von Kaufmann began his first experiments in photopolymer gravure after reading an article in a trade journal about the New York photographer Peter Liepke, which aroused his curiosity. Peter Liepke first produced platinum/palladium prints or gum prints from his New York photographs, and then had a ‘Special Photogravure Edition’ printed on the etching press.

As a photographer, Ralph von Kaufmann had already been working exclusively digitally for many years. However, he did not want to return to the analogue darkroom with all its photochemistry. The classic heliogravure process, in which a photographic motif is etched into the copper plate using acid, was also out of the question for him. So he looked for a way to combine his photography with photogravure. In the process, Ralph von Kaufmann became aware of the still very new technique of photopolymer gravure printing. It took him a year and many experiments before he was able to print the first light etching the way he wanted it. The artist learnt intaglio printing with copper plate, oil paint and etching press from the printmaker Sven Wohlgemuth in Hamburg. Translated with DeepL.com (free version)

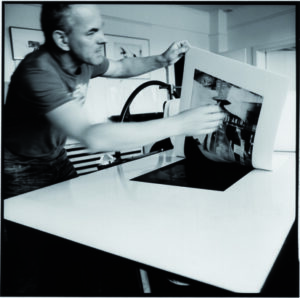

The intaglio etching technique is a ‘non-toxic intaglio printmaking’: instead of etching directly into the copper plate with toxic acid as in heliogravure, a thin layer of photopolymer is squeegeed onto the plate by hand in a darkened room with the help of a water atomiser. This layer is light-sensitive and still uncured. The remaining moisture between the copper plate and the polymer layer is pressed out in the etching press and the plate is then dried overnight in the dark. The next day, the printing plate is ready for exposure with the motif. The motif, which was previously printed on a transparent film in the finest possible resolution using an inkjet printer and black pigment ink, is then burnt into the printing plate in direct contact under vacuum with UV light. As the polymer only hardens when exposed to UV light, the black pigment ink of the inkjet printer has the advantage that it does not allow any light to pass through. As a result, the polymer remains soft under even the finest dots of black pigment ink during exposure. Consequently, every tiny black splash on the film from the inkjet printer leads to a depression in the printing plate and all the transparent areas on the film that let the UV light through harden the polymer layer. The image therefore consists of many tiny indentations into which the oil colour is rubbed. To expose the plate, Ralph von Kaufmann uses a 300kg contact copier from the analogue days of the Theimer company from the 1980s. This device contains a 1000 watt UV lamp and a heavy vacuum frame.

Before the intaglio plate can be rubbed with the oil colour, the soft unexposed polymer must be removed from the plate. To do this, the exposed plate is briefly placed in a bowl of washing suds or washing soda. The alkaline soda dissolves the soft polymer out of the wells. After a short intermediate soaking, the polymer layer with the indentations is fixed and hardened in an acidic vinegar bath.

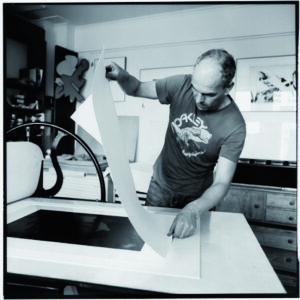

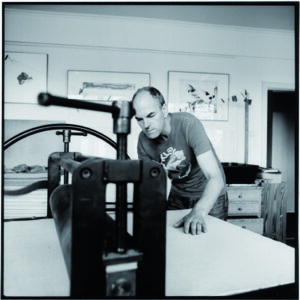

The subsequent print on paper is identical to the traditional copperplate engraving and the classic etching. The printing plate is rubbed with oil colour and carefully wiped out by hand in many passes with wiping gauze until the oil colour is only in the indentations. Once the plate is ready for printing, it is placed on the printing table of the etching press. A damp copperplate paper is carefully placed over it, the whole thing is covered with a printing felt and together the printing plate and copperplate paper are moved through the rollers of the etching press using a large flywheel. The pressure of the steel rollers, which weighs several tonnes, the moisture in the copper printing paper and the felt mat transfer the oil-based ink from the indentations in the printing plate to the paper. The print is complete. For each additional print, the printing plate is rubbed again with oil colour and wiped with gauze.

As the indentations are not etched into the copper plate with acid as with heliogravure, but are exposed in the photopolymer layer above it, the copper plate can be reused for other motifs after the edition has been printed. The photopolymer is removed from the copper plate by soaking it for a long time in a bath of washing suds.

Ralph von Kaufmann uses a copperplate paper from Hahnemühle for his intaglio prints. The genuine mould-made paper for artistic printing techniques is produced in individual sheets on a cylinder mould paper machine. It is acid-free and resistant to ageing. All etchings are original prints made by the artist himself.

Share the page with others

Mobile:

Fone:

Email:

Post: